Flow sensors are critical components in various applications, from industrial processes to medical devices. Their primary function is to measure the rate at which a fluid or gas flows through a system, providing essential data for control and monitoring. This blog will delve into the workings of flow sensors, their types, applications, and the benefits they offer.

What is a Flow Sensor?

A flow sensor is a device that measures the flow rate of liquids or gases within a pipe or duct. The measurement can be done in terms of volume flow rate (how much fluid passes through the sensor per unit of time) or mass flow rate (the mass of the fluid passing through the sensor per unit of time). These sensors are crucial in ensuring the proper functioning of various systems by providing accurate flow measurements that help maintain optimal conditions.

Types of Flow Sensors

There are several types of flow sensors, each suited to specific applications and environments. Here are the most common ones:

- Differential Pressure Flow Sensors

These sensors measure the difference in pressure across a constriction within the flow path. This pressure difference is proportional to the flow rate, allowing accurate measurement. They are commonly used in applications where precise control of fluid flow is necessary.

- Thermal Mass Flow Sensors

Thermal mass flow sensors measure the heat transferred from a heated element to the fluid flowing past it. The heat transfer rate is proportional to the mass flow rate, making these sensors ideal for applications requiring mass flow measurements.

- Ultrasonic Flow Sensors

Ultrasonic flow sensors use sound waves to measure the flow rate. They send ultrasonic pulses through the fluid and measure the time it takes for the pulses to travel from one sensor to another. The difference in time is used to calculate the flow rate. These sensors are non-invasive and suitable for measuring the flow of liquids and gases.

- Electromagnetic Flow Sensors

Electromagnetic flow sensors work on the principle of Faraday’s law of electromagnetic induction. They measure the fluid’s voltage as it flows through a magnetic field. This voltage is proportional to the flow rate. These sensors are ideal for applications involving conductive fluids.

Applications of Flow Sensors

Flow sensors find applications in a wide range of industries and scenarios. Some of the key applications include:

- Industrial Processes

In industrial settings, flow sensors monitor and control the flow of liquids and gases in various processes. This ensures the systems operate efficiently and safely, maintaining the desired performance levels.

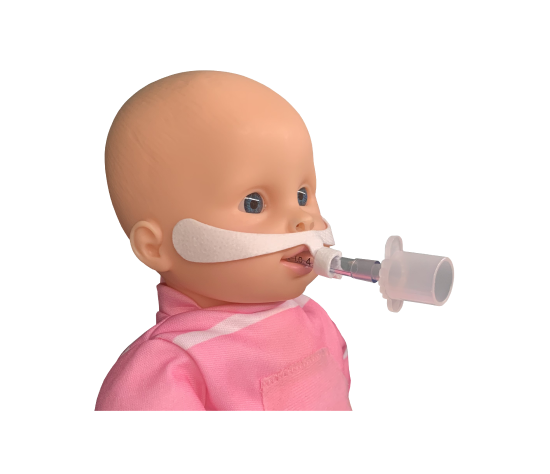

- Medical Devices

Flow sensors are crucial in medical devices such as ventilators, where accurate airflow measurement is essential for patient safety and effective treatment. B&B Medical Technologies, for instance, utilizes advanced flow sensor technology in its respiratory care products to ensure precise monitoring and control.

- HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, flow sensors are used to measure and control the flow of air and refrigerants. This helps in maintaining optimal indoor air quality and energy efficiency.

- Automotive Industry

Flow sensors are used in automotive applications to measure fuel flow, ensuring optimal engine performance and efficiency. They also monitor the flow of air and other fluids within the vehicle.

Benefits of Using Flow Sensors

Flow sensors offer numerous benefits across various applications. Some of the key advantages include:

- Improved Efficiency

By providing accurate flow measurements, flow sensors help optimize system performance, improving efficiency and reducing energy consumption.

- Enhanced Safety

Flow sensors play a crucial role in maintaining safe operating conditions by ensuring that the flow rates remain within desired limits. This is particularly important in applications where deviations in flow rates can lead to hazardous situations.

- Cost Savings

Accurate flow measurement helps reduce waste and prevent overuse of resources, leading to significant cost savings. This is particularly beneficial in industrial processes and HVAC systems.

- Better Control and Monitoring

Flow sensors provide real-time data that can be used for monitoring and controlling various processes. This leads to better decision-making and improved overall system performance.

Choosing the Right Flow Sensor

Selecting the appropriate flow sensor for a specific application involves considering several factors, including the type of fluid or gas, the required accuracy, the operating conditions, and the particular requirements of the system. Choosing a sensor compatible with the measured liquid or gas is important and can operate effectively under the given conditions.

Conclusion

Flow sensors are indispensable components in numerous applications, providing accurate and reliable measurements crucial for the efficient and safe operation of various systems. Flow sensors ensure optimal performance and control in industrial processes, medical devices, HVAC systems, or the automotive industry. With technological advancements, companies continue to innovate, offering state-of-the-art flow sensor solutions that meet the evolving needs of different industries. Understanding flow sensors’ types, applications, and benefits can help you select the right sensor for your specific needs, improving efficiency, safety, and cost savings.